How to Make Paper Bags with Paper Bag Making Machine

Article Structure

Introduction

With the advancement of science and technology and the development of automation, paper bag-making machines have been continuously upgraded, with smaller sizes and more complete functions. So, how do we use paper bag-making machines to make paper bags? In this article, we use the fully automatic model of Poseipack as an example to explain step by step.

Step 1: Prepare the raw materials(Paper Roll)

Preparing raw materials is the first step in making paper bags. Paper bags made from different raw materials have different characteristics. We will choose different raw materials according to different paper bags: including

White cardboard Roll

Kraft paper Roll

Coated paper Roll

Recycled paper Roll

Laminated paper Roll

Click here to learn about the characteristics of different raw materials.

The raw materials of our paper bag-making machines are often large industrial paper rolls. These industrial paper rolls are produced by paper mills, and these paper mills have low production costs because of large-scale production. Directly purchasing large industrial paper rolls for the next step of paper bag processing is currently the most economical and fastest production process for making paper bags.

Step 2: Slitting the paper roll

Place the purchased large industrial paper roll on the paper bag making machine, and use the slitting machine on the paper bag making machine to cut the large industrial paper roll into suitable sizes. The specific size depends on the model of the paper bag making machine you use. Then proceed to the next step of processing.

Step 3: Printing Raw Materials (Optional)

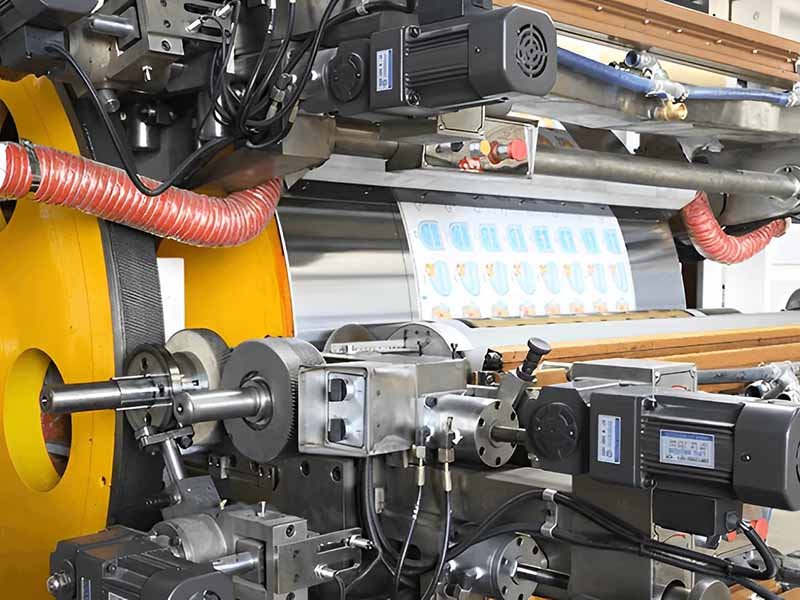

Next, the slit paper rolls are fed into the printing machine unit (optional) for printing. Two-color printing, four-color printing, six-color printing and eight-color printing are supported, and you can choose according to your needs. Flexographic printing is often used for printing, which is one of the most suitable printing methods for large paper rolls. This process is carried out simultaneously with the slitting step.

Step 4: Paper bag forming

The forming part is the core part of the paper bag-making machine. The paper raw materials will be formed in this part and finally become paper bags. There are four steps in total:

1. Paper cutting

The cutting mechanism punches and cuts at specific positions of the paper as required to meet the needs of bag making.

2. Forming:

The paper enters the forming mechanism, and a large number of forming rollers assist in folding and shaping.

3. Gluing:

The formed paper is glued together, and the required handle or transparent film is added in this step, which will be glued together with the formed paper. After gluing, the paper bag is already a semi-finished product.

4. Bottom sealing:

The semi-finished paper bag is sealed with glue at the bottom, and now a completely finished paper bag has been made.

Step 5: Paper Bag Collection

The conveying mechanism of the paper bag making machine will continuously convey the finished paper bags and collect them at the bag outlet, which is convenient for the next step of quality inspection and packaging.

Production precautions:

Be sure to pay attention to whether the paper type and weight match the machine parameters! Coated paper, white cardboard, and kraft paper have different characteristics, so the machine parameters need to be adjusted to adapt to different raw materials.

conclusion

The above is the whole process of how to make paper bags with paper bag making machine. We have complete paper bag packaging machinery solutions. Buy automatic paper bag making machine to create more profits for you.

Share:

More Posts

Understanding Paper Bag Materials in One Article

What materials are paper bags made of? What are the characteristics of each material? This article will tell you.

Paper Bag Types Explained

What are the types and characteristics of modern paper bag packaging? Here is the most complete explanation.