Popular Science: Paper bag types and characteristics

Article Structure

Introduction

Over the past two hundred years, paper bags have always been the preferred type in the packaging industry due to their economic and environmental performance. With the rise of plastic bags, paper bags have been in decline for a while, but with the improvement of human environmental awareness, the popularity of paper bags has increased again. With the advancement of manufacturing technology, people can now add more functions to paper bags to meet their needs.

In this article, Poseipack, as a paper bag-making machinery manufacturer, will explain the current mainstream paper bag types and characteristics from the perspective of production and manufacturing.

At present, the types of paper bags can be simply summarized as follows:

Square bottom paper bags

V bottom paper bags

Paper bags with handles

Paper bags with windows

D-cut paper bags

Printed paper bags

Waterproof and oil-proof paper bags (composite paper bags)

Envelope bags

Square bottom paper bags

Square bottom paper bags are one of the most widely used types of paper bags on the market. They are also the oldest type of paper bag. They have been around since the handmade era. The bottom of the square bottom paper bag is a flat square that can stand on its own. Under the same volume, square bottom paper bags are the most capable paper bags. Both KFC and McDonald’s have used square bottom paper bags for nearly half a century. Square bottom paper bags are also the most basic type of paper bag, commonly used in the retail industry. The top of the square bottom paper bag can be rolled up, which has a certain moisture-proof effect. In today’s automatic production by machines, the structure of square bottom paper bags has not changed much.

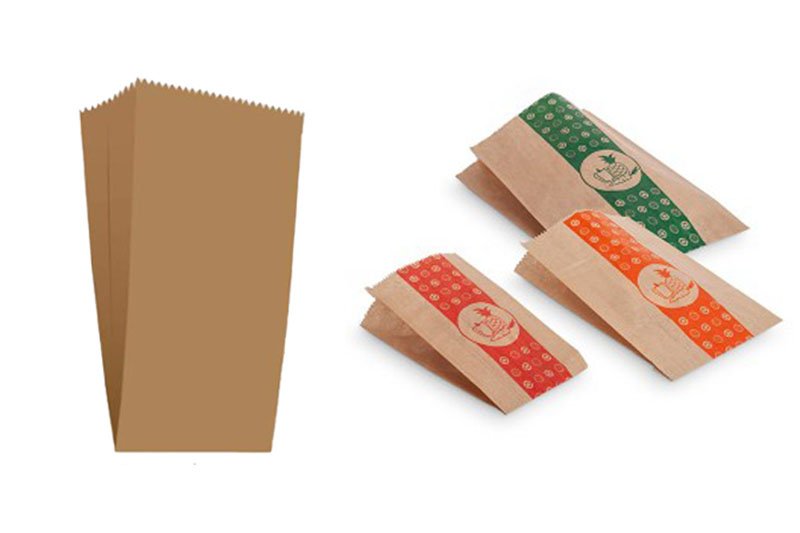

V bottom paper bags

V-bottom paper bags are also called pointed-bottom paper bags. As the name implies, the bottom is pointed. The overall side looks like the letter V. This type of paper bag is easy to produce and does not need to be folded and glued like square-bottom paper bags. There is one less process in manufacturing, so the manufacturing cost will be low and the manufacturing speed will be fast. At the same time, the structure is simple, the material requirements are low, and when it is not unfolded, it is as thin as a piece of paper, which is very suitable for transportation. In East Asia, due to cost reasons, V-bottom paper bags are widely used by small roadside vendors. Poseipack’s lowest-priced paper bag making machine is the V-bottom paper bag making machine. If you are looking for a cheap paper bag making machine, then the V-bottom paper bag making machine is your first choice.

Paper bags with handles

A paper bag with handles is a traditional paper bag with a pair of handles added to it. The handles are often made of paper. Structurally, this type of paper bag is divided into two parts: one is the paper bag body, and the other is a separate handle. The paper bag body can be made of kraft paper or printed white cardboard. The handles can be made of paper rope, paper handles, or nylon rope. This type of paper bag looks more high-end and elegant and is easy to carry. It is often used in the field of high-end packaging.

At the production level, Poseipack’s paper bag making machine supports the customization of three types of paper bag making machines with handles, namely, rope handle paper bags, flat handle paper bags, and inward folding flat handle paper bags.

Paper bags with windows

This type of paper bag emerged with the development of the plastic industry. The earliest paper bags did not have transparent windows. Users could only open the paper bag to see what was inside, which was very inconvenient. So, paper bags with transparent windows appeared. Paper bags with windows are often used in the food industry. A transparent plastic film is added to the side of the paper bag, which looks like a transparent window from the outside, allowing consumers to easily see the items inside so that they can make better choices when purchasing. This type of paper bag is widely used for single items such as bread and desserts.

D-Cut Paper Bags

D-cut paper bags have a D-shaped punched hole in them. This punched hole looks like the letter D. You can easily open this paper bag by just passing your hands through the D-shaped punched hole. This D-shaped punched hole can also be used as a handle. D-cut paper bags are often easier to manufacture than paper bags with handles, so many companies choose D-cut paper bags.

Printed paper bags

Printed paper bags are paper bags with printed patterns on them to promote the brand. When printing technology was immature, it was very difficult for people to print on paper bags in batches, and the cost of brand promotion was also very high. With the rapid development of printing technology and automation technology, it has become very easy to mass-produce printed paper bags. Printed paper bags have naturally become an important means of low-cost brand promotion. Everyone knows McDonald’s and KFC, and they are among the first companies to use printed paper bags. Today, Poseipack produces and provides fully automatic printed paper bag-making machines. Contact us; you can print 2 colors, 4 colors, or 6 colors on the paper bags according to your needs, and we can provide a complete mechanical solution.

Waterproof and oil-proof paper bags

Waterproof and oil-proof paper bags are also called composite paper bags, which are made of other materials and paper. There is a layer of film inside this paper bag, which can be aluminum foil or plastic film. It can not only isolate water and oil, but also has the function of heat preservation. Composite paper bags feel more reliable and high-end. Of course, the cost is also higher.

Envelope bags

Envelope bags are the earliest application of paper bags. At that time, they were only used to hold paper documents. In the past, a piece of paper was folded in half by hand and simply smeared with glue to create an envelope bag. Nowadays, this process can be completed by machines. With the development of the times, envelope bags are not only used to hold letters but are more often used to hold lightweight express deliveries and documents.

Reduce manufacturing costs with poseipack's mechanical solution

Poseipack‘s various high-speed automated paper bag-making machines can provide a complete solution for paper bag production. We have paper bag-making machines, printing machines, paper bag handle-making machines, etc. Contact us for a complete paper bag-making solution.

conclusion

The above are the current mainstream paper bag types and explanations. No matter which kind of paper bag it is, it is a product of a specific usage scenario. Poseipack has a complete paper bag packaging solution machinery. According to your usage scenario, you can choose the right paper bag to help your packaging business reach a higher level.

Share:

More Posts

how to make paper bag

How to make paper bags with a paper bag making machine? What are some things you must know?This article will explain step by step.

Understanding Paper Bag Materials in One Article

What materials are paper bags made of? What are the characteristics of each material? This article will tell you.